What is a Sludge Press and How Does it Work in 2026?

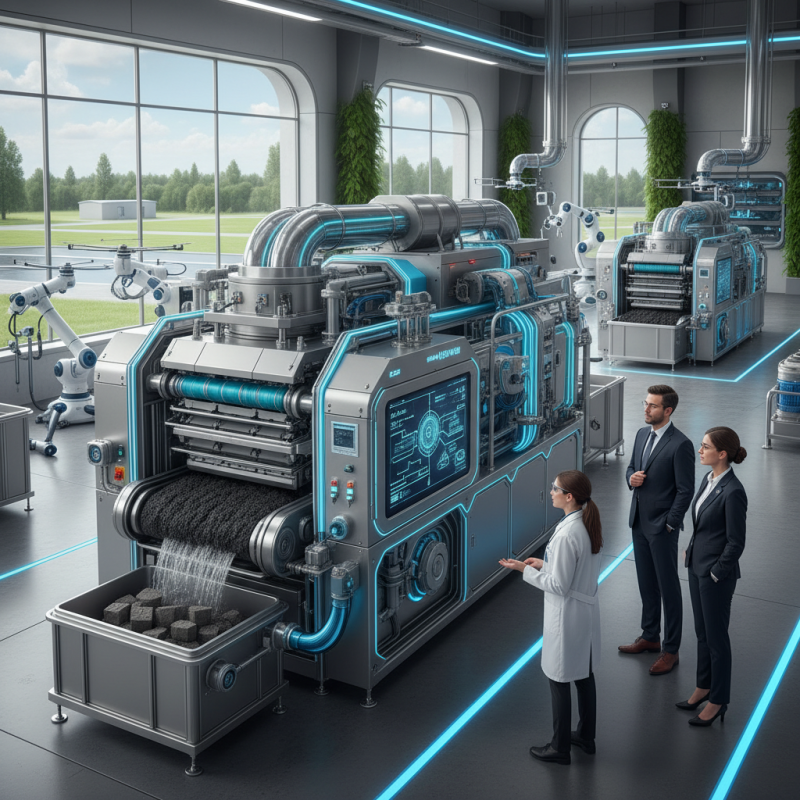

In 2026, the innovation surrounding the "Sludge Press" continues to evolve. As one industry expert, Dr. Emily Harper, states, “A Sludge Press is crucial for wastewater treatment efficiency.” This technology plays a vital role in processing and dewatering sludge, transforming it into manageable by-products.

The mechanics of a Sludge Press involve squeezing the moisture out of sludge, minimizing waste volume. This energy-efficient solution is key for municipalities and industries alike. However, many still overlook its importance in sustainable practices. Decision-makers sometimes struggle with the initial investment costs. Yet, the long-term environmental benefits can far outweigh the drawbacks.

The integration of cutting-edge technology in Sludge Press systems also remains a focal point. Despite advancements, challenges like maintenance and reliability persist. As we look forward, it is essential to address these issues to enhance performance. This will ultimately improve the overall effectiveness of wastewater management systems worldwide.

What is a Sludge Press? Definition and Overview

A sludge press is an essential piece of equipment used in wastewater treatment. It helps in dewatering sludge. By applying pressure, excess water is squeezed out from the sludge, resulting in a more manageable solid waste. This process reduces the volume of sludge, making disposal simpler and more cost-effective.

In 2026, data from industry reports indicate that about 50% of wastewater treatment plants utilize some form of sludge press technology. This trend highlights the growing importance of efficient waste management. The average reduction in sludge volume can reach up to 90%, significantly decreasing transportation and disposal costs. However, not all operators are satisfied with their results. Some plants report issues with clogging and maintenance, impacting efficiency.

The operational principles of a sludge press are not always straightforward. Variations in sludge composition can hinder efficient dewatering. Operators often struggle to maintain optimal pressure settings. This inconsistency can lead to variable performance. In some cases, additional chemicals are required to improve results, leading to increased operational costs. These challenges remind us that, despite advancements, there is still room for improvement in sludge management technologies.

The Importance of Sludge Press in Wastewater Treatment

In the realm of wastewater treatment, the sludge press plays an essential role. This equipment helps dewater sludge effectively. As urban areas grow, more wastewater needs processing. Inevitably, the volume of sludge produced increases, making efficient treatment crucial. A well-functioning sludge press can significantly reduce the water content in sludge, leading to lower disposal costs.

The importance of a sludge press goes beyond sheer functionality. It aids in conserving resources. By reducing the water content, facilities save energy when transporting sludge. However, the process isn't without challenges. Some operators may underestimate the maintenance needs of the press. Without proper upkeep, efficiency decreases, resulting in increased costs.

Regular monitoring and adjustments are vital for optimal performance. Focusing on these aspects can provide better treatment outcomes, despite any initial learning curve. The intricate balance of efficiency and reliability is where the real importance lies.

How a Sludge Press Operates: Key Mechanisms Explained

A sludge press is essential in wastewater treatment processes. It optimizes the solid-liquid separation by using hydraulic pressure. Typically, this equipment helps reduce the volume of sludge. Recent studies reveal that a well-functioning sludge press can decrease waste volume by up to 90%. This efficiency is crucial as facilities seek to manage increasing waste generated by urbanization.

The operation of a sludge press involves several key mechanisms. First, the feed sludge enters the press chamber. Gravity helps the solid particles settle at the bottom. The pressing mechanism then applies varying levels of pressure to squeeze out trapped water. Reports indicate that modern presses use pressures between 30 to 70 bar, depending on sludge composition. This pressure drastically enhances dewatering efficiency, making sludge easier to handle and dispose of.

Despite these benefits, there are challenges. Not all sludge types respond well to this technology. Some sludges can thicken or create blockages within the press. Regular maintenance is thus vital for optimal performance. Additionally, training operators is essential to recognize when adjustments are necessary. Neglecting these factors could reduce the press's efficiency, resulting in operational downtime. Insights into these shortcomings highlight the need for innovation in sludge processing.

What is a Sludge Press and How Does it Work in 2026?

| Feature | Description | Efficiency | Applications |

|---|---|---|---|

| Dehydration Process | Utilizes mechanical force to separate solid sludge from liquid waste. | Up to 90% waste volume reduction. | Wastewater treatment plants, industrial processes, and municipal sewage. |

| Automation | Modern sludge presses are equipped with automated controls for efficient operation. | Reduces labor costs and increases operational reliability. | Used in various industries for consistent sludge management. |

| Material Use | Constructed from durable materials to withstand corrosive sludge types. | Enhances longevity and minimizes maintenance. | Applicable in chemical, food processing, and bioenergy sectors. |

| Energy Efficiency | New models implement energy-saving technologies for improved performance. | Can reduce energy consumption by up to 30%. | Essential for environmentally conscious operations. |

Types of Sludge Presses: Comparing Technologies and Designs

Sludge presses play a key role in wastewater treatment. In 2026, various technologies offer distinct advantages and limitations. Each type of sludge press is designed to tackle specific challenges in managing sludge. For instance, belt presses utilize gravity to separate water from solids. They are easy to operate but may not achieve the highest dewatering efficiency.

On the other hand, screw presses use a rotating screw to exert pressure on the sludge. This method often results in better compaction but can require more maintenance. Another option is the plate and frame press, which offers high performance but can be expensive to maintain. Each design presents trade-offs.

When choosing a sludge press, one must consider factors like footprint, maintenance, and processing capacity. The decision should not be taken lightly. Operational challenges can arise unexpectedly. This reflects the need for careful evaluation and potential adjustments in the process. Understanding the nuances of each technology can lead to more effective sludge management strategies.

Future Trends: Innovations in Sludge Press Technology by 2026

The future of sludge press technology shows promising innovations by 2026. A report from the Global Water Intelligence estimates that the global market for sludge management is expected to exceed $20 billion by 2026. This growth is driven by the increasing demand for sustainable waste treatment solutions. Many facilities are looking for ways to reduce energy consumption while maximizing efficiency.

Advancements in automation and artificial intelligence are bringing significant changes. New sludge presses are likely to feature smart sensors that monitor performance in real-time. This data can enhance the efficiency of dewatering processes. However, integration with existing systems remains a challenge. Facilities often face the difficulty of retrofitting older machines.

Another trend is the use of advanced materials in construction. These materials can improve durability and reduce maintenance costs. Research indicates that using polymer-based filters could boost the filtration rate by nearly 30%. Yet, costs associated with these new materials can be high. Operators must weigh the benefits against budget constraints. Overall, the landscape of sludge press technology is rapidly evolving, but it still faces numerous hurdles.

Article Source: