How to Maintain a Cooling Tower Efficiently?

cooling towers are critical components in many industrial processes. They help dissipate heat from systems, ensuring equipment operates efficiently. According to a report by the U.S. Department of Energy, improper maintenance can lead to a 30% increase in energy consumption. This highlights the need for effective cooling tower maintenance strategies.

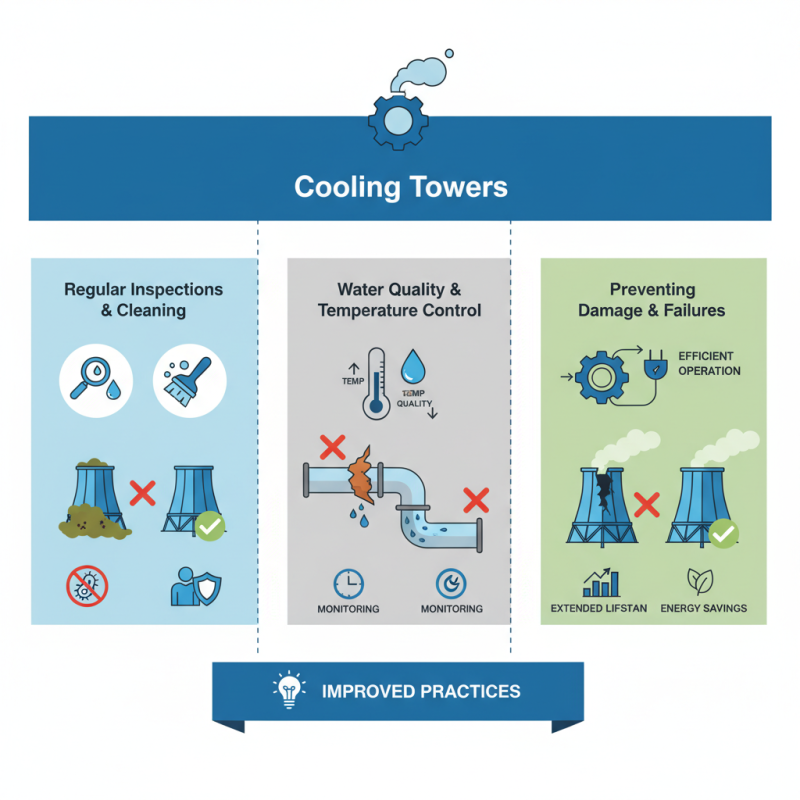

Regular inspections and routine cleaning are essential. Dirty cooling towers can become breeding grounds for bacteria, potentially leading to Legionnaires' disease, as noted by the Centers for Disease Control and Prevention (CDC). These health risks are unacceptable in today’s health-conscious environment. Additionally, scaling and corrosion from untreated water can reduce a cooling tower's lifespan.

Keeping a cooling tower in optimal condition requires attention to detail. For instance, water quality and temperature control should be monitored closely. Neglecting these factors can lead to failures that disrupt operations. Reflecting on these aspects can prompt facility managers to initiate better practices, ultimately leading to more efficient cooling operations.

Understanding the Role of Cooling Towers in Industrial Processes

Cooling towers play a crucial role in industrial processes. They are essential for dissipating excess heat. This heat management is vital for machine efficiency. According to industry reports, up to 30% of energy costs come from cooling. Proper maintenance can significantly reduce these costs.

Operational efficiency depends on how well cooling towers are maintained. The cooling process should remain effective to avoid overheating equipment. Regular inspections help identify problems early, which can prevent costly repairs and downtime. It’s recommended to clean cooling towers quarterly. Dirt and scale buildup can impair efficiency.

Tip: Monitor water quality regularly. Poor water quality can lead to corrosion and scaling, which ultimately affects the cooling capacity. Additionally, keeping fan motors in good condition ensures optimal airflow. Make it a practice to check fan bearings and belts often. Small changes in operation can yield significant energy savings.

Key Components and Their Functions in Efficient Cooling Tower Operation

Cooling towers play a crucial role in industrial and commercial processes. Understanding key components is essential for their efficient operation. The primary components include the fan, fill, and basin. The fan circulates air, while the fill increases the area of contact between water and air. This maximizes heat transfer, enhancing cooling efficiency. The basin collects water, ensuring the system operates smoothly.

Regular maintenance is necessary to keep these components in optimal condition. Inspecting the fan for wear can prevent unexpected breakdowns. Sometimes, debris accumulates in the fill, reducing its efficiency. This can lead to water stagnation, which might encourage algae growth. It's important to clean this regularly, though many facilities overlook it.

The system's water quality is also vital. High levels of minerals can lead to scaling. This buildup affects heat transfer and efficiency. Conducting regular water quality tests is often neglected, but it’s an essential task. Simple adjustments can create significant improvements. Examining these elements can reveal areas for better performance.

How to Maintain a Cooling Tower Efficiently? - Key Components and Their Functions in Efficient Cooling Tower Operation

| Component | Function | Maintenance Tips | Impact on Efficiency |

|---|---|---|---|

| Fan | Circulates air through the cooling tower | Inspect and clean regularly to prevent dust buildup | Directly affects air flow and cooling efficiency |

| Heat Exchanger | Transfers heat from the water to the air | Check for leaks and clean surfaces regularly | Improper maintenance can lead to decreased cooling capacity |

| Water Distribution System | Ensures even distribution of water across the fill media | Inspect for clogs and ensure even flow | Critical for maintaining optimal flow rates |

| Fill Media | Increases the surface area for heat exchange | Regularly check for fouling and replace as needed | Effectively impacts thermal performance |

| Drift Eliminator | Reduces water loss by capturing water droplets in airflow | Inspect for damage and replace if necessary | Improves water conservation and efficiency |

Regular Maintenance Practices to Enhance Cooling Tower Performance

Regular maintenance is crucial for cooling towers to operate efficiently. According to industry reports, poor maintenance can result in a 30% reduction in cooling efficiency. Inspecting and cleaning the water basins regularly can prevent algae growth and scale formation. These issues can greatly hinder heat exchange processes. It’s essential to remove sediment build-up. Ignoring this can lead to overheating and even failure.

Routine inspections also play a vital role. Checking fan and pump operations ensures that the system runs smoothly. A malfunctioning fan can increase energy consumption by up to 25%. Vibration and noise can indicate underlying issues. Regularly monitoring these factors can save on costly repairs. Many cooling towers require an annual inspection, but monthly checks can catch problems early.

Water quality is another critical aspect. Testing for chemical levels protects against corrosion and scaling. Not maintaining proper pH levels can lead to significant damages. A report revealed that half of cooling tower issues stem from improper water treatment. Operators need to be vigilant. Neglecting these practices not only reduces efficiency but can also lead to regulatory fines.

Monitoring System: Essential Metrics and Best Practices for Cooling Towers

Effective monitoring of cooling towers can significantly enhance their efficiency. Key metrics include water temperature, flow rate, and energy consumption. According to the Energy Research Council, improving monitoring practices can cut energy costs by up to 30%. Regularly checking temperature differentials keeps the system within optimal ranges. This ensures better heat exchange and reduced operational costs.

Implementing a data logging system is crucial. It helps collect and analyze data over time. Consistent monitoring can highlight inefficiencies. For instance, if flow rates fluctuate unexpectedly, it may indicate a blockage. Research shows that many facilities overlook small issues until they escalate. A proactive approach saves time and maintenance costs later on.

Metrics should be tracked continuously. The American Society of Mechanical Engineers recommends automated systems for real-time data. However, many facilities still rely on manual checks, leading to gaps in data accuracy. Creating a culture of continuous improvement is necessary. Regular training for staff can enhance monitoring efficiency. By prioritizing these metrics, facilities can optimize cooling tower performance while reducing environmental impact.

Energy Efficiency Strategies: Reducing Operational Costs in Cooling Towers

Cooling towers play a crucial role in heat exchange systems. Optimizing their energy efficiency can dramatically reduce operational costs. Regular maintenance is vital. Check water levels and temperature regularly. Cleaning the tower helps ensure optimal performance. Accumulation of debris can hinder efficiency.

One effective strategy is to install variable frequency drives (VFDs) on fan motors. This adjustment allows for better control of fan speed based on load demands. Another action is to conduct periodic water quality tests. Contaminated water can lead to increased energy consumption. It might seem overwhelming at first, but small changes can yield significant savings.

Monitoring and analyzing energy consumption is essential. Keep an eye on your cooling tower's performance data. Unexpected spikes might indicate inefficiencies. Sometimes, maintenance routines can become routine and overlooked. Small lapses can lead to higher costs over time. Always seek ways to improve your system and reflect on past decisions for better outcomes.

Cooling Tower Energy Efficiency Strategies

This chart illustrates the estimated cost savings associated with implementing various energy efficiency strategies in cooling towers. Regular maintenance offers significant savings, while efficient pumps provide the highest reduction in operational costs.

Article Source: