Best Ball Screws for Sale What to Consider Before Buying?

When considering a "ball screw for sale," it's important to understand the nuances of this critical component in machinery. Ball screws convert rotary motion into linear motion efficiently. According to a recent report by the Machinery Components Association, the demand for high-precision ball screws has surged by 15% annually. This growth reflects the increasing reliance on automation across industries.

Expert John Smith, a leading figure in motion control technology, emphasizes, "The right ball screw can enhance productivity and accuracy significantly." However, selecting the best product requires careful consideration of factors like load capacity and operational speed. The market is flooded with options, yet not all are ideal for every application. Each project demands specific requirements, making thorough research essential.

Buyers should also reflect on their long-term needs. Is the initial investment worth the performance gain? With numerous brands and models available, navigating the choices can be daunting. It's vital to balance quality with cost while ensuring that the selected ball screw meets both current and future demands.

Understanding the Basics of Ball Screws and Their Applications

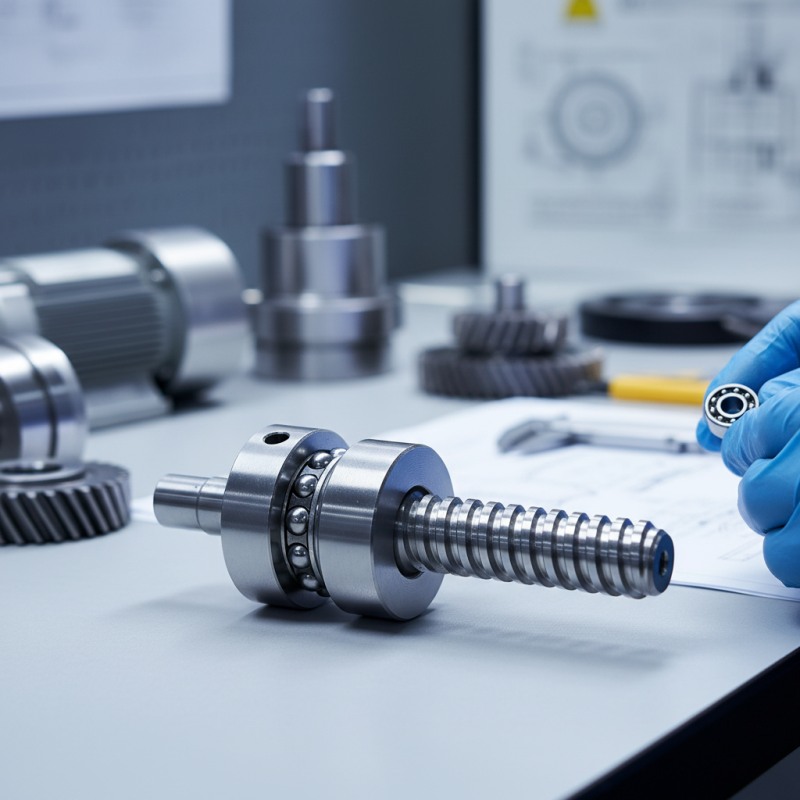

Ball screws are essential linear motion components in various applications. They convert rotational motion into linear motion through rolling elements. Industries utilize them in machinery, robotics, and automation. Ball screws improve accuracy and efficiency, making them popular in precision tasks. A report from the TechSci Research indicates that the global ball screw market is set to grow at a CAGR of 8% from 2021 to 2026. Understanding their design and mechanism is crucial for effective application.

When considering ball screws, pay attention to load capacity and critical speed. Each project has unique demands, such as axial load and speed requirements. For instance, high precision applications often require a higher lead accuracy. To enhance performance, ensure proper lubrication and maintenance. Tips: Regular inspection can help identify wear and tear. This may save costs in the long run.

Keep in mind that not all ball screws are equal. Variations exist in design and materials. They may not fit every application perfectly. In some cases, experimenting with different types may yield the best results. Tips: Test various models for better compatibility. Be open to reflecting on your choices in selecting ball screws.

Key Factors to Consider When Choosing Ball Screws for Your Project

When selecting ball screws for your project, several key factors should be evaluated. The first is the load capacity. Understanding the maximum load a screw can handle ensures it meets your project's demands. Overloading can lead to premature failure, so it’s crucial to align specifications with your application needs.

Another factor is the screw's lead and diameter. These dimensions influence the speed and precision of movement. A larger diameter often allows for greater load capacity. However, it also affects the system's overall weight and motion. Consider what balance works best for your project.

Additionally, lubrication is significant for performance. Different types of lubrication impact operation efficiency and lifespan. Some projects may benefit from grease, while others may require oil. Evaluating the operating environment is essential, as contaminants can affect your choice of lubrication. Balancing these considerations may not yield perfect results, but they guide you towards the best decision for your task.

Comparing Different Types of Ball Screws: Which is Right for You?

When choosing the right ball screw for your application, various factors come into play. For instance, consider the lead of the screw. A finer lead offers more precision but moves slower, while a coarser lead allows for quicker movement at the cost of accuracy. Think about what matters most in your project.

There are several types of ball screws to choose from. Flanged ball screws are ideal for limited space, as the flange provides easy mounting options. On the other hand, ground ball screws offer higher accuracy, making them suitable for intricate tasks. It's vital to weigh the practicality versus the precision you need.

Don’t forget the load capacity. Some designs handle heavy loads better than others. If you plan to use it in a high-stress environment, this aspect requires careful consideration. Assessing these differences might lead you to rethink your immediate choices.

Evaluating Manufacturer Reliability and Warranty Options

When considering best ball screws for sale, evaluating manufacturer reliability is crucial. A trustworthy manufacturer should have a solid reputation. Look for reviews and testimonials. They provide insight into product quality and customer service. Not all manufacturers meet high standards. Some may cut corners to save costs.

Warranty options play a significant role in your decision. A good warranty can offer peace of mind. It indicates the manufacturer's confidence in their product. Short warranty periods can be a red flag. Pay attention to what the warranty covers. Does it include parts and labor?

Tips to remember: Always ask about warranty terms before buying. Check if the manufacturer has support available after the sale. Inquire about repair and replacement policies. A reliable manufacturer will be transparent about these details. Consider manufacturers who prioritize customer feedback. Their responsiveness can reflect a commitment to quality.

Cost vs. Quality: Making an Informed Decision on Ball Screws

When considering ball screws, cost and quality often clash. It's easy to focus solely on price. However, lower-priced products may lack durability and precision. A cheap ball screw can lead to errors and costly downtime in production. It's vital to weigh long-term savings against initial costs.

Quality ball screws are often made from premium materials. They offer better performance and longevity. Investing in higher quality may seem daunting, but it can prevent future headaches. Look for detailed specifications. Understand the load capacity and efficiency ratings. Examine user reviews and testimonials.

Pay attention to the manufacturers' reputation. A reliable vendor stands behind their products. Sometimes, even slightly more expensive options offer improved features and support. It’s essential to find a balance that fits your specific needs. You may need to explore several options, which requires patience and research. Each decision can impact operational effectiveness. Reflecting on these aspects can help clarify your choice.

Cost vs. Quality of Ball Screws

Article Source: